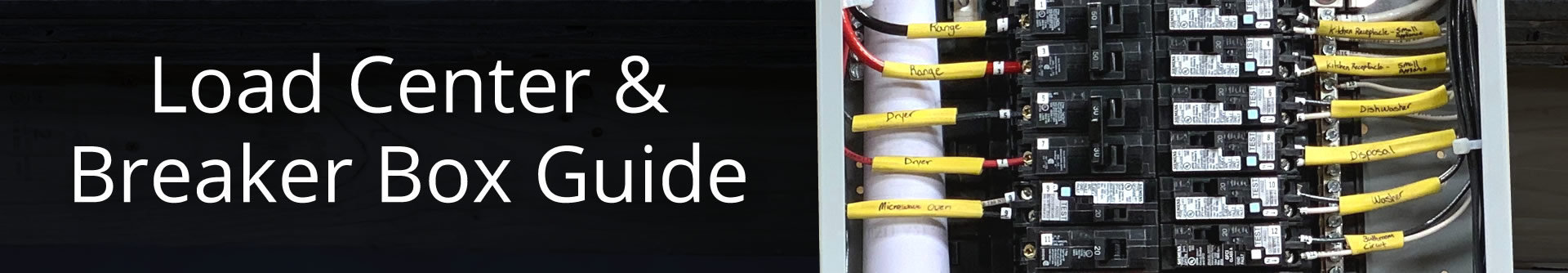

Circuit Breaker Box (Load Center) and Electrical Panel Board Products

Load Centers, Panelboards & Subpanels:

How Does a Breaker Box or Load Center Work?

A circuit breaker box (also known as a load center) is the component of a residential or commercial electricity supply system that distributes electrical power

into subsidiary (branch) circuits while also housing protective fuses or circuit breakers for each circuit. If an electrical short or overload occurs, the circuit

breaker automatically disconnects power to prevent potential damage, electrical fires, and/or personal injury.

What is a Breaker Box Commonly Called?

The term "breaker box" is the most common name for this important part of your home's electrical system, but it is also known by several other names.

The name that is used most often may vary depending on the region or country. Some other names for a breaker box are load center, electrical panel, breaker panel,

main panel, service panel, circuit breaker box, fuse box, DB box, panel box, and distribution board.

How to Know if a Load Center or Circuit Breaker Meets Safety Standards?

Load centers and circuit breakers must meet certain standards and requirements per the International Electrotechnical Commission (IEC) and the National Electrical

Manufacturers Association (NEMA). Elliott Electric Supply offers a variety of these products at industry standard.

What's the Difference Between a

Main Electrical Panel Box and Sub Panel?

Main electrical panel: Known as a breaker box or load center, this is the foundation of any building's electrical

circuits and systems. The main electrical service panel activates, controls, and regulates power supplied by a utility company as electricity comes

from the meter through service conductors to the main panel.

Sub panel: Sometimes called a satellite panel, a sub panel breaker box can be added to segment power from the main

electrical panel into a separate, downstream load center. Once installed, subpanels have their own breakers and circuits that originate from a single

power circuit from the main electrical panel. A sub panel board, typically a Main Lug Only (MLO) type load center, can be placed anywhere on a

structure and allows electricians to safely add extra circuits without replacing the main panel. It's important to note, however, that the power

/ amperage demands of a sub panel cannot exceed the capacity provided by the main electrical panel, and the subpanel requires an isolated and

insulated neutral bar as well as a ground bar.

What Is a Circuit Breaker?

Circuit breakers are safety mechanisms designed to prevent damage or fire resulting from an excess or surge of electrical current. With tens of thousands of

fires annually resulting from electrical damage or malfunction, the National Electrical Code® (NEC) requires electrical safety features in residential and

commercial construction, and circuit breakers are one of those requirements.

How Do Circuit Breakers Work?

A standard circuit breaker is rated by wattage and amperage, and they operate by automatically separating (breaking) electrical contacts which

interrupts the flow of electricity when a fault is detected. This separation can occur via tensioned spring, compressed air, thermal expansion,

or magnetic field, depending on the voltage class and type of breaker. A typical circuit breaker features a reset lever, reset button, or reset

switch, and it can be found in a wide variety of settings from low-current residential circuits and appliances to high-voltage commercial,

industrial, and municipal systems, depending on the rating and type. Additionally, breakers can feature single pole, double pole, or more

(three or four) poles to control additional circuits that share a neutral wire for specific installations.

What are the different types of circuit breakers?

Standard circuit breakers:

These are the most basic type of circuit breaker and are used to protect circuits from overloads and short circuits. They have a single switch that

trips when the current exceeds the breaker's rating.

Ground fault circuit interrupters (GFCIs):

GFCIs are designed to protect against electrical shock. They work by detecting small imbalances in the current flowing through the hot and neutral wires.

If an imbalance is detected, the GFCI will trip and cut off power to the circuit.

Arc fault circuit interrupters (AFCIs):

AFCIs are designed to protect against fires caused by arc faults. Arc faults occur when electricity arcs across two conductors that are not supposed to be

connected. AFCIs can detect arc faults and trip to cut off power to the circuit before a fire can start.

Types of Circuit Breaker by Design: Magnetic, Thermal, Molded

Circuit breakers are available in numerous construction and structural types such as Magnetic Circuit, Thermal Magnetic, and Molded Case circuit breakers.

Magnetic

Circuit Breaker

A magnetic circuit breaker is the most common type of breaker used in the US and is primarily used in low-current circuits (less than 100 amps).

A magnetic circuit breaker is kept closed by a spring-latching mechanism that gets released by an electromagnetic solenoid when a fault is detected.

Shop Standard Magnetic Breaker

Thermal Magnetic

Circuit Breaker

A thermal magnetic circuit breaker features bi-metal switches that can detect heat and are triggered by large overloads However, thermal magnetic breakers

allow smaller overloads to persist, permitting short current spikes that are required for electric motors or other non-resistive loads. A thermal magnetic

circuit breaker can also be sensitive to ambient temperature.

Shop Thermal Magnetic Breaker

Molded Case

Circuit Breaker

A Molded Case Circuit Breaker (MCCB) is used for robust residential, commercial, and industrial applications, including heavy current circuits

(up to 2500 A). MCCBs protect motors, switchgear, and industrial or telecom equipment from overloads or short circuits at high amperage. Some

molded case breakers can communicate trip data electronically.

Shop Molded Case Breaker

Warning: When using this information to perform electrical work, call a licensed electrician or consult the NEC® for safety. All

licensed electricians have passed examinations covering the National Electric Code®, know state and local building codes, and may carry insurance to cover damages.